30 hits

Ship strength, vibration and noise, durability, welding, etc

Ship

1. Hull Structural Strength and Fatigue Analysis (as shown in Figure 1)

Application Scenarios:

Longitudinal Strength: Simulates hull sagging/hogging deformations in waves (e.g., bending moment distribution of a 100,000 DWT container ship in wave heights of 6m).

Local Strength: Stress concentration analysis of strong frames and side shell plating in cargo hold areas (e.g., bulkhead buckling check for a VLCC - Very Large Crude Carrier).

Regulatory Compliance: Meets classification society rules (e.g., DNV GL, ABS), such as requiring a yield strength safety factor ≥ 1.67.

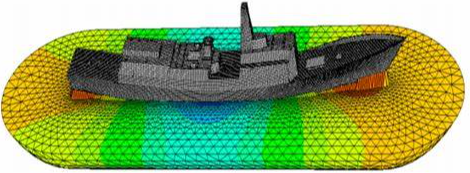

2. Wave Loads and Motion Response (as shown in Figure 2)

Analysis Scope:

Hydrodynamic Coupling: Calculates heave and roll responses in regular/irregular waves (spectral analysis frequency range: 0.1–2.0 Hz).

Slamming Loads: Impact pressure on bow bottom in extreme sea conditions (peak values may reach several MPa).

Tools: Coupled simulations using AQWA, WAMIT, and FEA.

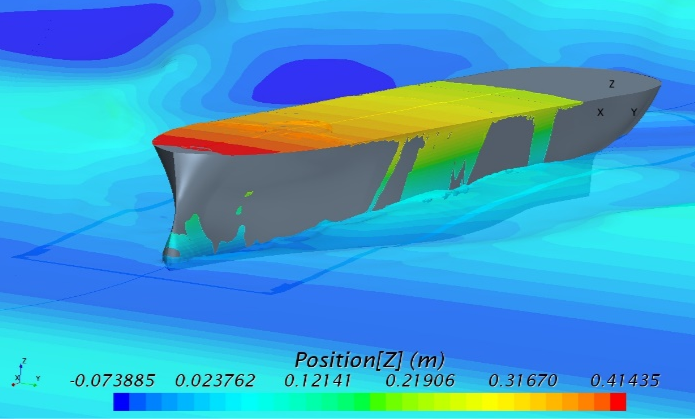

3. Ice-Class Vessel Structural Design (as shown in Figure 3)

Key Challenges:Highly nonlinear ice loads (localized pressure may reach 10–20 MPa)

FEA Applications:Ice-strengthened structures: Simulation of contact mechanics during hull-ice collisions (e.g., side shell structure of Russian ARC7 ice-class LNG carriers).

Fatigue life assessment: Prediction of weld crack initiation cycles under Arctic navigation conditions (e.g., 25-year service life requirement for polar route vessels).

4. Vibration and Noise Control

Problem Scenarios:

Main engine vibration transmission: Dynamic response analysis of low-speed diesel engine foundations (e.g., MAN B&W 12K98ME mounting system).

Acoustic comfort: Noise control in luxury cruise cabins (target value <45 dB(A)).

Methodology: Modal analysis coupled with acoustic FEA (using software such as VA One).

5. Composite Vessel Optimization

Application Areas:

Lightweight high-speed crafts: Carbon fiber hull layup design (e.g., 0°/±45° ply optimization).

Corrosion-resistant structures: Stiffness and impact resistance analysis of FRP (fiberglass reinforced plastic) fishing vessel decks.

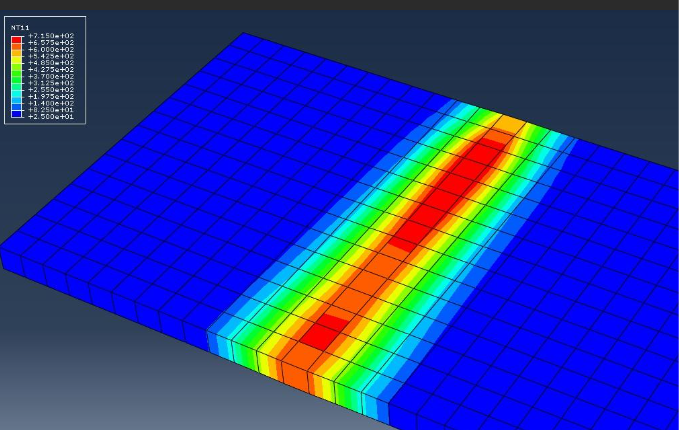

6. Welding and Manufacturing Process Simulation (as shown in Figure 4)

Key Issues:

Welding distortion: Angular deformation prediction in hull block butt welds (precision control ±2mm).

Residual stress: Stress distribution optimization in thick-plate (50mm+) multi-pass welding.

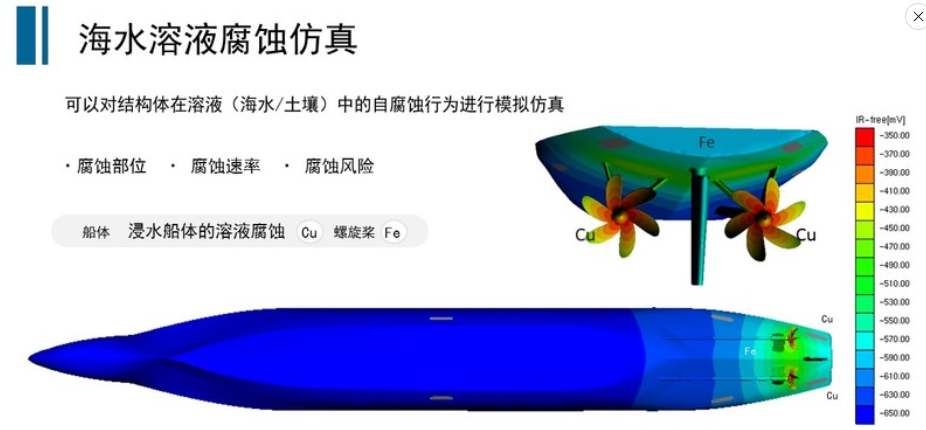

7. Corrosion and Life Prediction (as shown in Figure 5)

Analysis Methods:

Electrochemical coupling: Simulation of seawater corrosion rates (e.g., 0.1-0.3mm/year corrosion loss for marine steels).

Residual strength: Ultimate load capacity evaluation of hull plating with corrosion defects.

Fig.1 Strength of hull structure

Fig.2 Analysis of ship impact by waves

Fig.3 Analysis of ship icebreaking structure

Fig.4 Welding analysis

Fig.5 Prediction and analysis of ship corrosion life

Contact:

Prof. Tian:WhatsApp:+86 15029941570 | Mailbox:540673737@qq.com

Copyright © 2025.Boye Engineering Technology All rights reserved. Yue ICP17017756Num-1