33 hits

Provides accurate electromagnetic analysis

Motor Design and Optimization

Size and Topology Optimization:

Rapid evaluation of different stator/rotor structures, slot types, pole shapes (e.g., V-shape, straight-bar, Halbach array), air gap dimensions, and permanent magnet (PM) arrangements (surface-mounted, interior) to assess performance impact and identify optimal designs.

Magnetic Circuit Optimization:

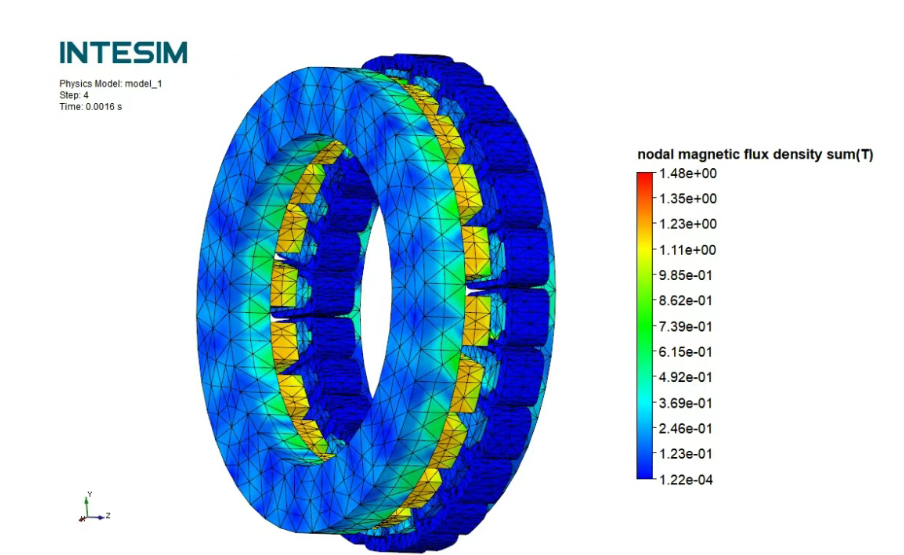

Precise calculation of magnetic flux density distribution to identify local saturation zones.

Optimization of magnetic paths (e.g., magnetic bridges, flux barriers) to improve magnetic utilization and prevent excessive saturation.

Material Selection Assessment:

Comparative analysis of different silicon steel grades and PM materials (e.g., NdFeB, ferrite, SmCo) on motor performance (efficiency, torque density, cost).

Winding Design:

Optimization of winding types (concentrated, distributed), turns, parallel branches, and pitch to meet target back-EMF, inductance, resistance, and MMF harmonic requirements.

Performance Prediction and Analysis:

No-Load Characteristics:

Precise calculation of back-EMF waveform, amplitude, and harmonic content.

Cogging torque computation and optimization.

Load Characteristics:

Steady-state and transient output torque, torque ripple, efficiency, power factor, and input current/voltage waveforms (including harmonics).

Inductance Parameter Calculation:

Direct and quadrature-axis inductance (Ld, Lq), winding self/mutual inductance, and saturation characteristics (current-dependent curves) for field-oriented control (FOC).

Loss Calculation:

Core Loss:

Hysteresis, eddy current, and excess losses computed using improved Steinmetz or Bertotti models, accounting for rotational magnetization and harmonic effects.

Copper Loss:

AC resistance increase due to skin and proximity effects, calculating ohmic losses in windings.

PM Eddy Current Loss:

Critical for high-speed motors or PWM-supplied drives, assessing PM temperature rise and demagnetization risk.

Stray Loss:

Estimation of stray losses in structural components (challenging to model precisely).

Electromagnetic Force & Vibration Noise Analysis:

Force Density Calculation:

Radial and tangential electromagnetic force distribution on stator teeth, yoke, and rotor using Maxwell stress tensor or virtual work method.

Force Wave Analysis:

Spatial orders and temporal frequencies of force waves to identify key excitation sources (e.g., 0th-order radial force, low-order modes) for NVH prediction.

Fault Diagnosis & Reliability Assessment:

Demagnetization Analysis:

PM operating point variation under extreme conditions (high temp, overload, short-circuit) to evaluate partial/full demagnetization risks

Local Saturation Analysis:

Identification of over-saturated zones affecting inductance, control accuracy, and efficiency.

Short-Circuit Fault Analysis:

Simulation of winding faults (turn-to-turn, phase-to-phase) to assess fault currents, torque spikes, and hazards.

Unbalanced Operation Analysis:

Performance under voltage imbalance or winding asymmetry.

Multi-Physics Coupling Analysis:

Electromagnetic-Thermal Coupling:

Losses (core/copper/PM eddy) as heat sources for temperature distribution prediction.

Electromagnetic-Structural Coupling:

Electromagnetic forces as loads for stress, deformation, and vibration analysis.

Electromagnetic-Control Coupling:

Co-simulation with control systems (e.g., FOC, DTC, sensorless algorithms) for system-level validation.

Control Strategy Research & Validation:

High-fidelity motor parameters (inductance, back-EMF constant, flux linkage) for control algorithm design.

Hardware-in-the-loop (HIL) or software co-simulation to test FOC, direct torque control (DTC), flux weakening, and sensorless strategies.

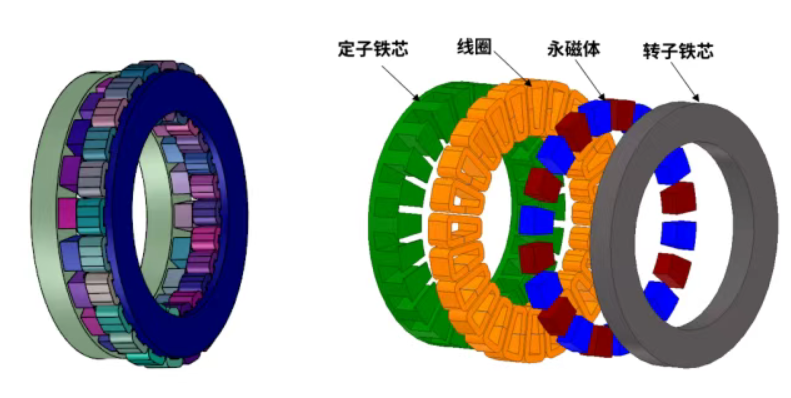

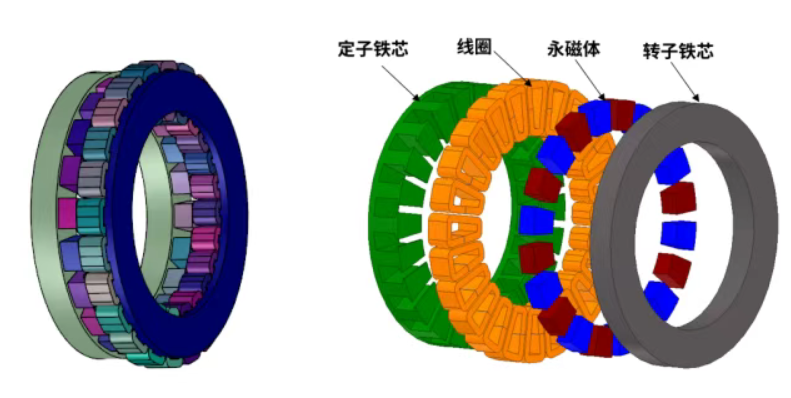

Fig.1 Geometry model of axial flux permanent magnet synchronous motor

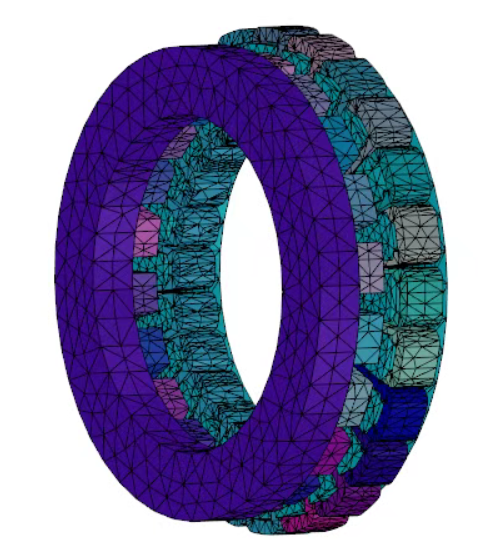

Fig. 2 Meshing

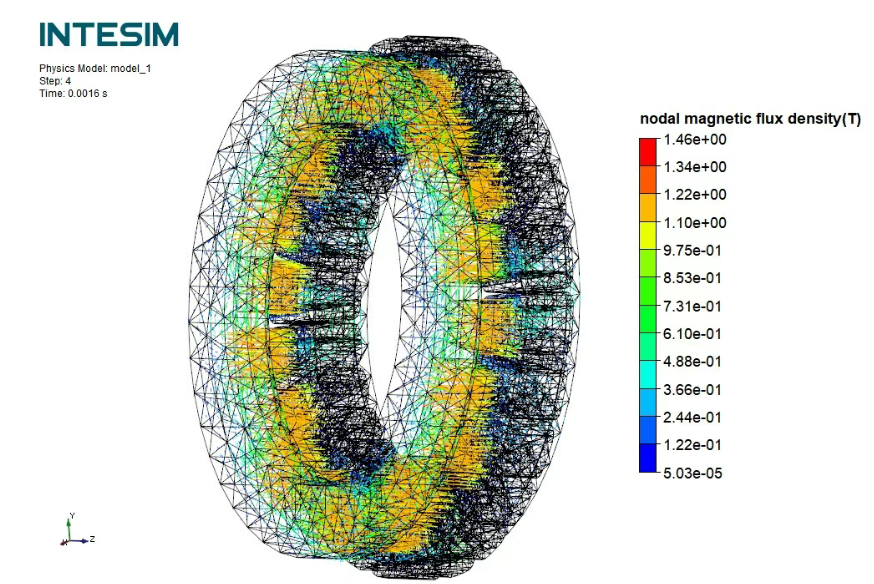

Fig. 3 INTESIM magnetic density cloud diagram

Fig.4 INTESIM magnetic density vector diagram

Contact:

Prof. Tian:WhatsApp:+86 15029941570 | Mailbox:540673737@qq.com

Copyright © 2025.Boye Engineering Technology All rights reserved. Yue ICP17017756Num-1