28 hits

Turbine static analysis, modal analysis, structural optimization

Finite Element Analysis of Aircraft Engine Turbine Blades

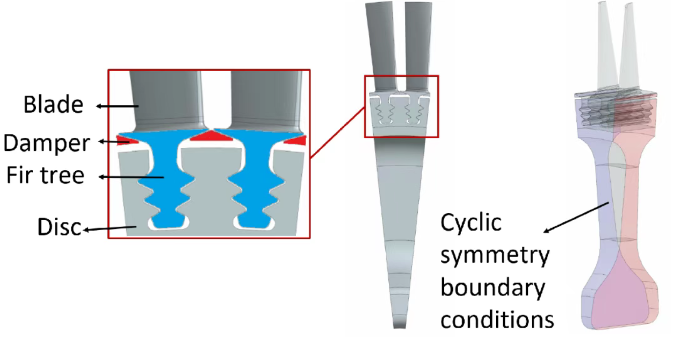

In the analysis of the bladed disk structure, the geometry, applied loads, and boundary conditions exhibit precise symmetry about the turbine's rotational axis. The cyclic symmetry assumption can be employed to reduce computational effort. Leveraging this symmetry, the finite element model scope is first reduced to a single sector for analysis, after which the results from this sector are expanded to all other sectors to obtain the full system solution.Accordingly, to construct the finite element model and perform the necessary analyses, a turbine sector comprising 1/60th of the full system (containing two blades) was modeled.

Figure 1 Complete blade disc with leaf root damper

Finite Element Model Description

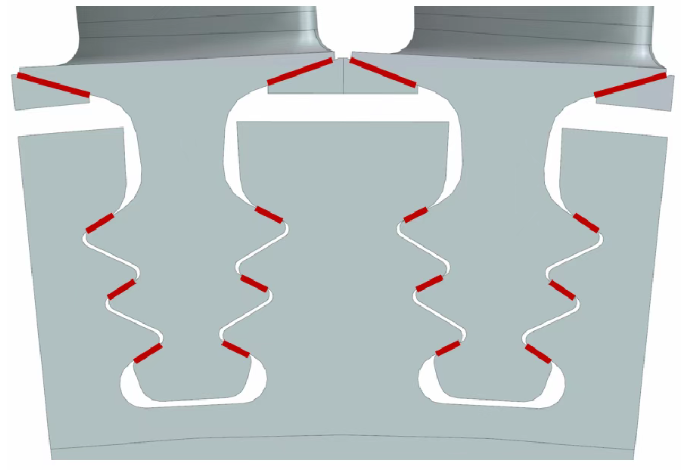

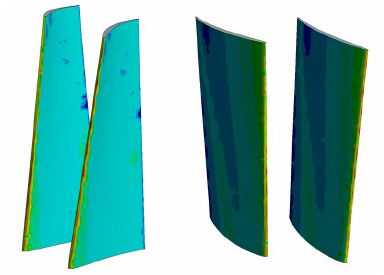

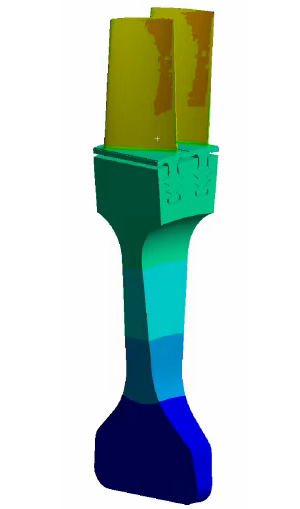

The modeled sector consists of two blades, blade root dampers, fir-tree-shaped tenons, disk components, and their interfacial contacts, as illustrated in Figure 2. The finite element model comprises 171,523 SOLID185,elements85,932 nodes and 257,796 degrees of freedom. Additionally, 5,512 contact nodes were assigned to the interaction zones, interconnected through a Coulomb friction model. Figure 3 specifically details the contact interfaces between:Blades and dampers,Fir-tree tenons and disk.

Figure 2 The geometry used to construct the finite element model

Figure 3 Contact surface

Static Analysis

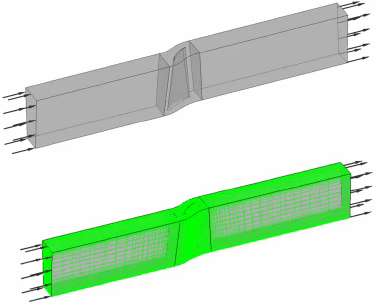

The static analysis is conducted to account for the effects of static loads and conditions, thereby enabling more accurate results for subsequent modal analysis and time-domain dynamic simulations. In this example, the static model incorporates cyclic symmetry and considers the following factors:Influence of steady-state temperature distribution on material properties,Rotational body force at 5,000 RPM,Static aerodynamic pressure loads acting on the blades and Pressure loads applied to both the pressure and suction surfaces of the blades.

Figure 4 Steady-state aerodynamic pressure load and temperature field

Figure 5 Static pressure loads acting on the blades

Figure 6 Temperature distribution in the steady state of the blade disk system

Modal Analysis

Following the static analysis, modal analysis was performed to investigate the structural dynamic behavior by determining natural frequencies and mode shapes. This modal analysis incorporated the combined effects of mechanical loads, temperature, and rotational body forces, with the static analysis results included as prestress conditions. The dynamic characteristics of the structure under these conditions were primarily obtained by solving the eigenvalue problem.

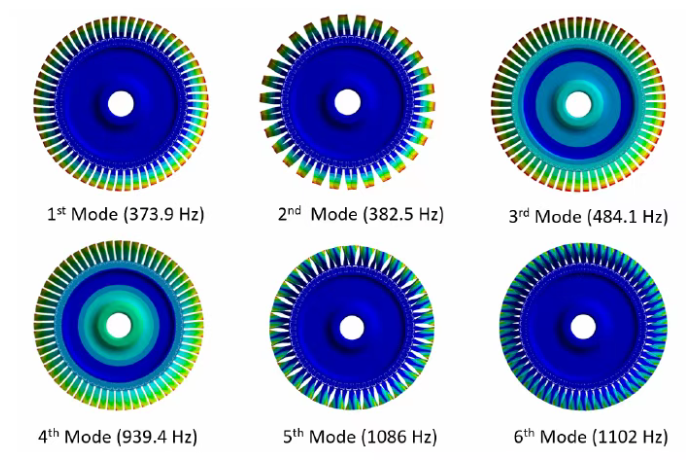

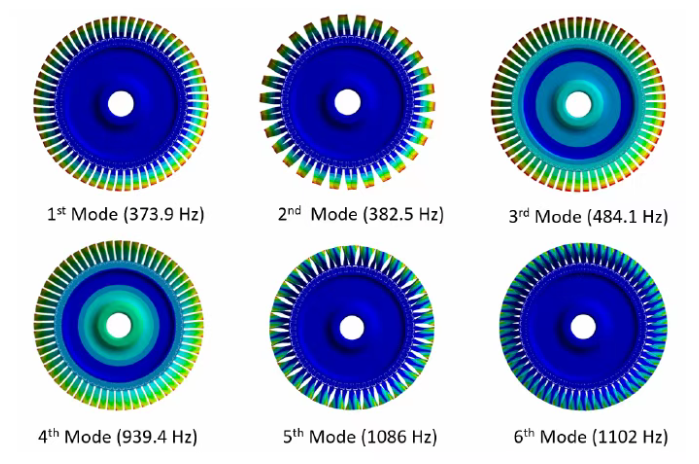

Figure 7 illustrates the first six mode shapes at harmonic index/nodal diameter 0, clearly demonstrating the manifestation of the system's cyclic symmetry in its vibration modes.

Figure 7 In the presence of a leaf root damper, the first 6th order mode under the 0th order harmonic index / node diameter

Modal Characteristics Analysis:

The first-order mode exhibits synchronous flapping motion of all blades, generating maximum deflection at the blade tips. This mode is particularly critical as it typically possesses the lowest natural frequency and is most susceptible to excitation during operation.The second-order mode demonstrates out-of-phase flapping behavior, where adjacent blades oscillate in opposite directions. This effectively counteracts partial system displacement and may reduce stress concentrations on the turbine disk.For the third and fourth-order modes, the presence of a single nodal circle indicates disk-participating modes, revealing more complex vibrational behavior. These blade modes combine both flapping and torsional motions, which are significant as they induce asymmetric loading on the disk, potentially affecting its fatigue life.The fifth and sixth-order modes return to zero nodal circles, displaying increasingly complex blade motions:Fifth mode: Coupled blade bending-torsion in out-of-phase pattern,Sixth mode: Coupled blade bending-torsion in in-phase pattern.

Contact:

Prof. Tian:WhatsApp:+86 15029941570 | Mailbox:540673737@qq.com

Copyright © 2025.Boye Engineering Technology All rights reserved. Yue ICP17017756Num-1