4 hits

FE-SAFE

fe-safe™: Finite Element-Based Fatigue Analysis Software

Today’s manufacturers face mounting pressures: using less material, delivering lightweight yet more reliable components in shorter timeframes, and minimizing warranty and recall costs....

Many companies leverage advanced finite element analysis (FEA) for stress calculations, but fatigue analysis often relies on manual stress point selection and tabular trial-and-error calculations. This process is time-consuming and unreliable, as critical failure locations can easily be missed. Fatigue testing of initial design prototypes in laboratories is also lengthy. If a prototype fails prematurely, it triggers costly, time-consuming cycles of redesign, retesting, and rework—delaying project completion and product delivery.

In the automotive industry, approximately 40% of total development costs are spent on physical prototypes. In the medical sector, an unexpected failure can result in delivery delays of months compared to competitors.

fe-safe™: A Powerful Finite Element-Based Fatigue Analysis Tool

fe-safe™ integrates seamlessly into your design workflow, empowering you to optimize designs and testing strategies with confidence. It reduces the need for physical prototype testing, lowers product recall risks, and cuts warranty expenses.

Key Capabilities of fe-safe™

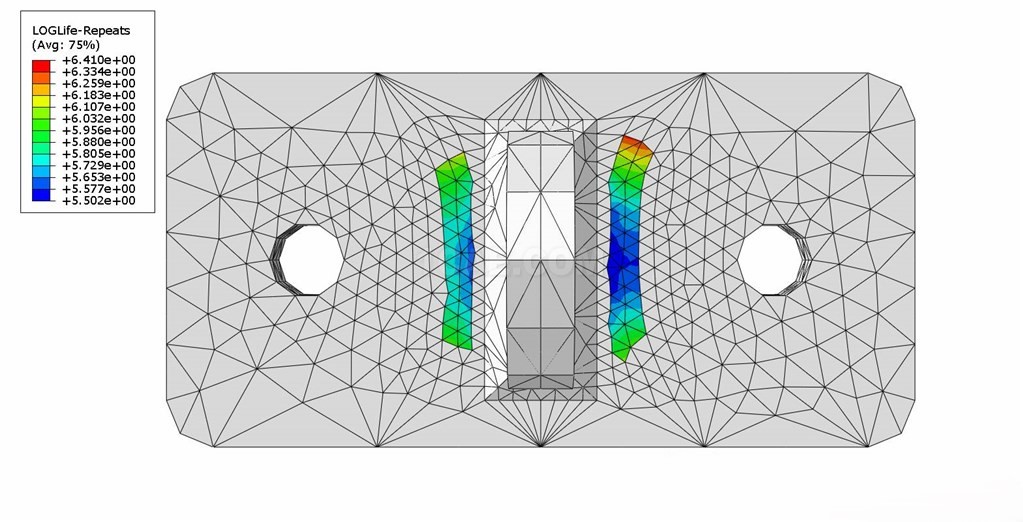

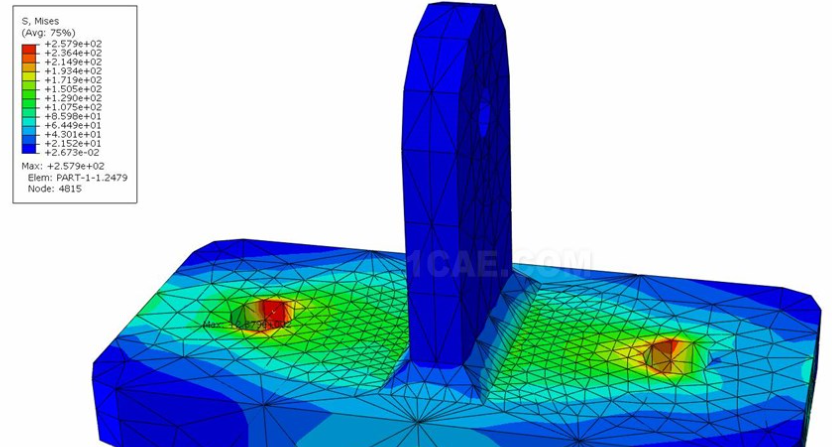

Comprehensive Fatigue Life Calculation: Computes fatigue life for every point on the model and visualizes results via contour plots, clearly identifying fatigue life spans and potential crack locations—ensuring no critical points are overlooked.

Design Optimization Insights: Determines the required stress reduction to achieve target design life, highlighting areas where strength meets requirements and where material savings are possible.

Probability-Based Life Estimation: Generates product life curves based on failure probability analysis.

Critical Part Prioritization: Identifies which components are most vulnerable during operation and which can be excluded from fatigue testing.

Non-Critical Load Identification: Flags non-essential loading conditions, potentially reducing the number of loads and test cycles required for prototype validation.

fe-safe™: More Than Just a Fatigue Analysis Tool

Design Knowledge Accumulation: Beyond calculating fatigue life, fe-safe™ reveals the root causes behind results. This builds design expertise, enabling faster, more optimized future designs.

Cost Efficiency: Delivers significant cost savings by drastically reducing manual effort. Even eliminating one prototype test or preventing a premature failure translates to substantial additional savings.

Trusted by Industry Leaders: Fe-safe™ is the preferred choice for optimizing structural designs and test plans among many of the world’s top 100 companies.

Technical Strengths

Speed: Analyzes multiple components and materials in a single run. fe-safe™ automatically adjusts analysis methods as materials change, while contour plots display node-specific fatigue life, structural strength indices, and survival probabilities—all calculated in one step.

Accuracy: Powered by advanced multi-axial algorithms at its core. Its node elimination technology balances speed and precision, with users reporting strong correlation between analytical results and physical test data. Continuous software development ensures fe-safe™ remains a technical leader.

Ease of Use: Automatically selects optimal algorithms based on chosen materials. It features direct interfaces with leading FEA software (ABAQUS, ANSYS, I-DEAS, Nastran, PRO/MECHANICA) and an intuitive, single-screen GUI for streamlined workflow.

Contact:

Prof. Tian:WhatsApp:+86 15029941570 | Mailbox:540673737@qq.com

Copyright © 2025.Boye Engineering Technology All rights reserved. Yue ICP17017756Num-1